OUR MACHINES

No. 1 Milling machine 6 AXES vertical

X=1200 Y=900 Z=500

No. 1 Milling machine 3 AXES vertical

X=510 Y=350 Z=450

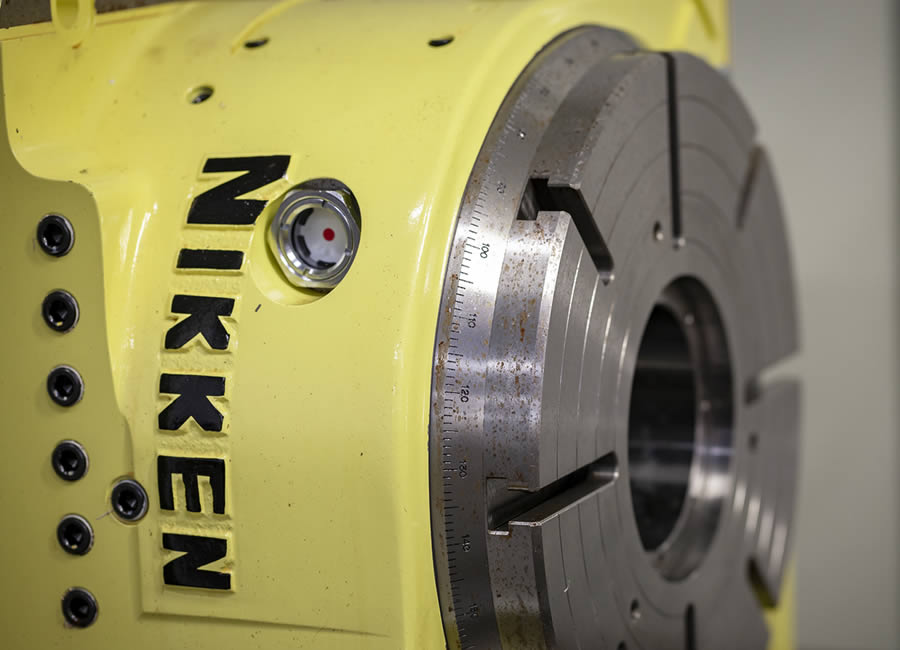

No. 1 Milling machine 4 AXES vertical ( divider)

X=700 Y=480 Z=640

No. 1 Milling machine 5 AXES vertical ( head+ divider)

X=1.550 Y=600 Z=450

No. 1 Milling machine 6 AXES vertical ( head+ table+ divider)

X=1.700 Y=600 Z=500

No. 1 Milling machine 5 AXES vertical ( head+ divider)

X=1.050 Y=600 Z=450

No. 1 Milling machine 6 AXES vertical ( head+ table+ divider)

X=1.400 Y=640 Z=500

No. 2 Milling machine 6 AXES vertical ( head+ table/ divider)

X=2.100 Y=700 Z=950

No. 1 Lathe CNC

D.max turnable=160 L=200 D.from bar= 32

No. 1 Lathe CNC

D.max turnable=720 L=2000

No. 1 Integrated turning center with adjustable milling head

D.max turnable=700 L=1.500 D.from bar= 70

No. 2 Wire EDM

X=450 Y=320 Z=162 U=+o-50 V=+o-50

No. 1 Microforatrice

X=350 Y=250 Z=340 D.fori da 0,20 a 6,35 mm

No. 1 Automatic Band Saw

max=275

No. 1 Rettificatrice Tangenziale

X=800 Y=500

No. 2 Traditional Milling machine vertical

No. 1 Traditional Lathe

No. 1 Universal Sharpener

X=1200 Y=900 Z=500

No. 1 Milling machine 3 AXES vertical

X=510 Y=350 Z=450

No. 1 Milling machine 4 AXES vertical ( divider)

X=700 Y=480 Z=640

No. 1 Milling machine 5 AXES vertical ( head+ divider)

X=1.550 Y=600 Z=450

No. 1 Milling machine 6 AXES vertical ( head+ table+ divider)

X=1.700 Y=600 Z=500

No. 1 Milling machine 5 AXES vertical ( head+ divider)

X=1.050 Y=600 Z=450

No. 1 Milling machine 6 AXES vertical ( head+ table+ divider)

X=1.400 Y=640 Z=500

No. 2 Milling machine 6 AXES vertical ( head+ table/ divider)

X=2.100 Y=700 Z=950

No. 1 Lathe CNC

D.max turnable=160 L=200 D.from bar= 32

No. 1 Lathe CNC

D.max turnable=720 L=2000

No. 1 Integrated turning center with adjustable milling head

D.max turnable=700 L=1.500 D.from bar= 70

No. 2 Wire EDM

X=450 Y=320 Z=162 U=+o-50 V=+o-50

No. 1 Microforatrice

X=350 Y=250 Z=340 D.fori da 0,20 a 6,35 mm

No. 1 Automatic Band Saw

max=275

No. 1 Rettificatrice Tangenziale

X=800 Y=500

No. 2 Traditional Milling machine vertical

No. 1 Traditional Lathe

No. 1 Universal Sharpener

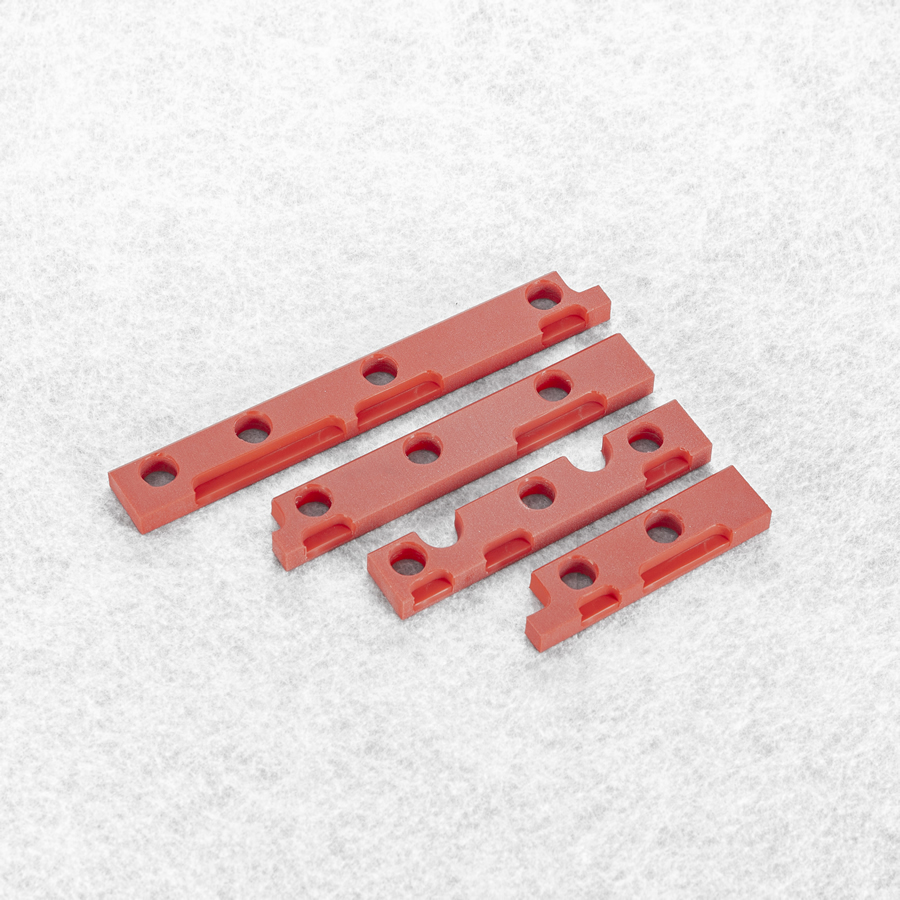

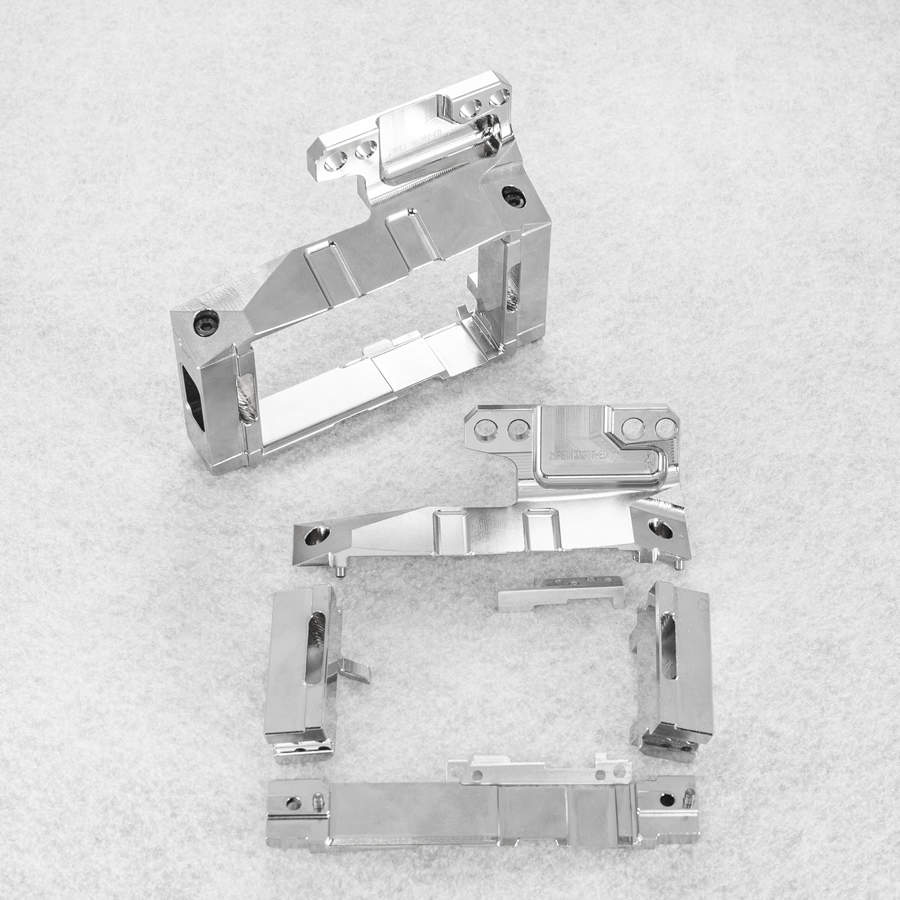

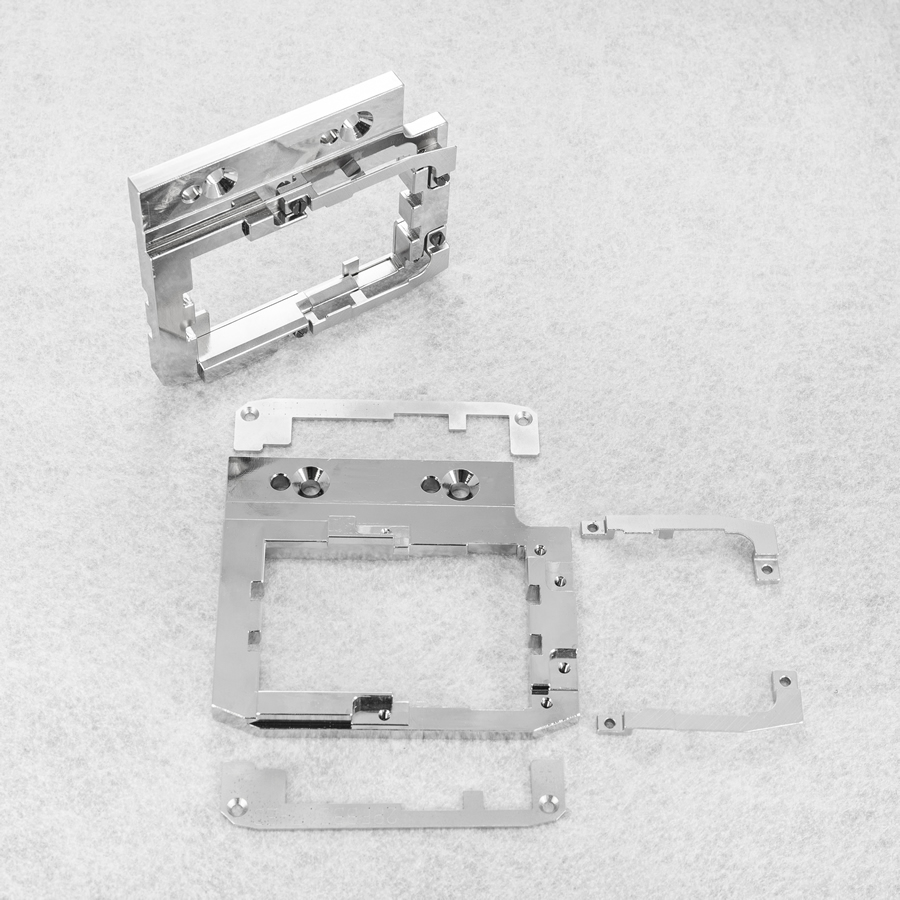

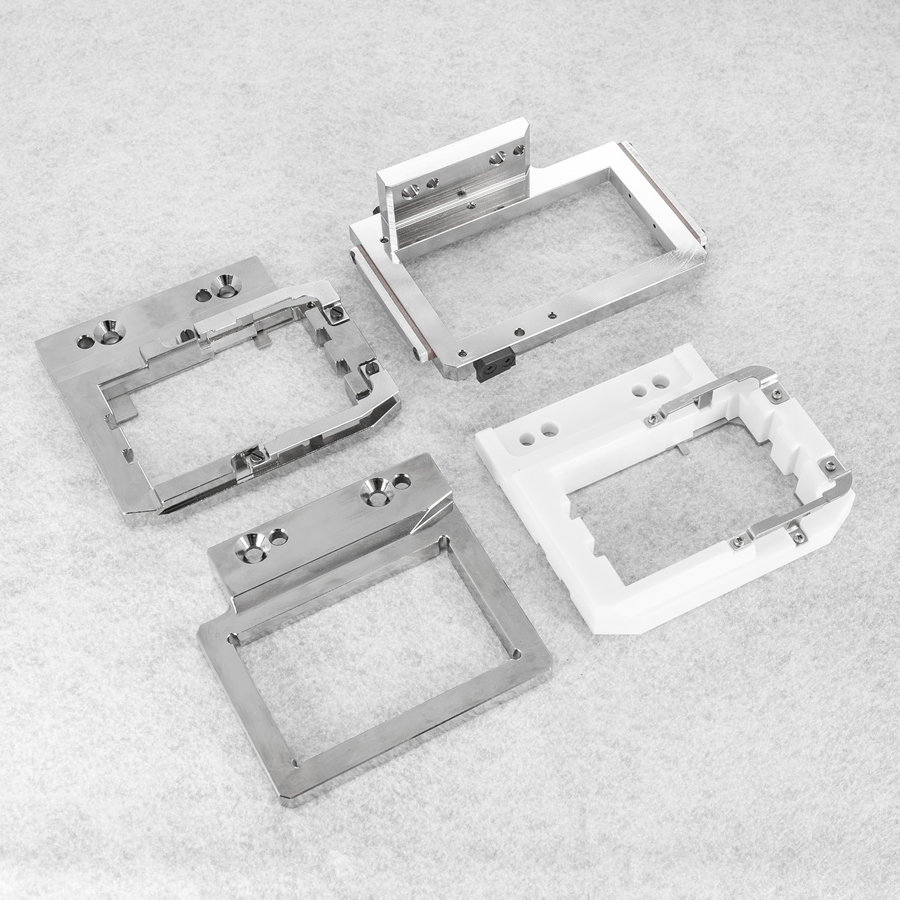

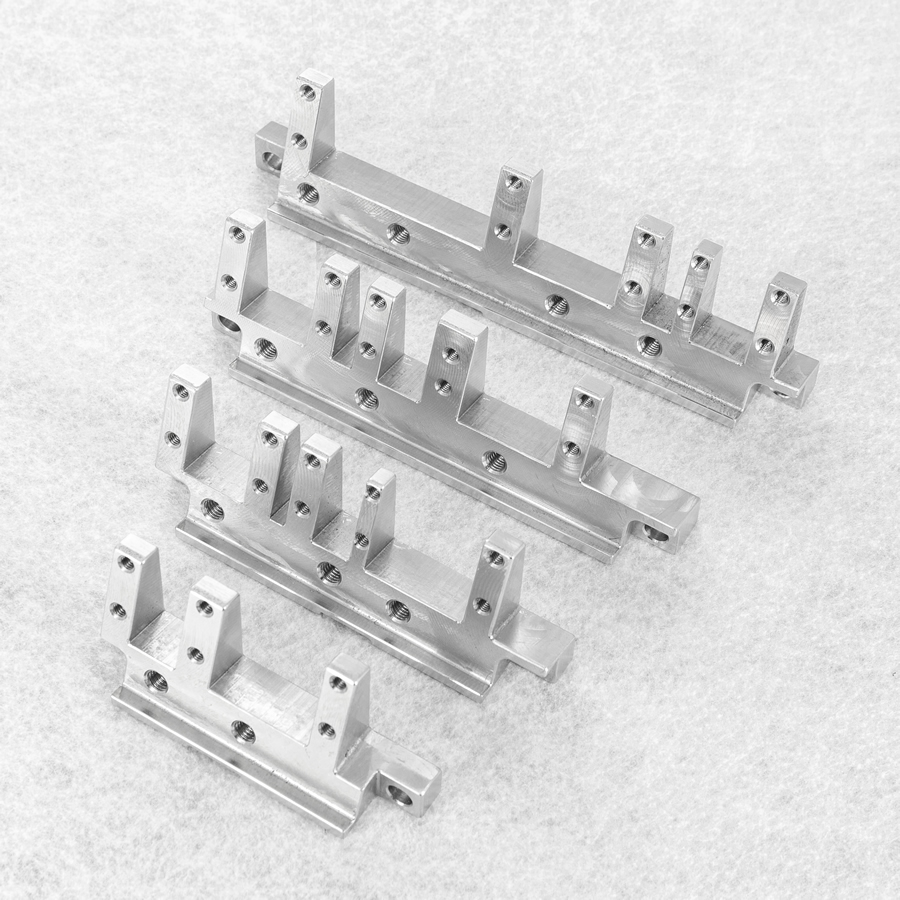

Our specialisation is "Format Parts"

Accorsi offers various finishes on many types of its processed materials.

OUR PROCESSES

SHARPENING

ADJUSTMENTS

LATHE-BORING

BORING

BARRELLING

BROACHING

TOOTHING

ELECTRICAL DISCHARGE MACHINING

FILLETING

DRILLING

MILLING

ENGRAVING

GLUEING

PART ASSEMBLY

PLANING

STRAIGHTENING

GRINDING

WELDING

DEBURRING

SLOTTING

WATER CUTTING

LASER CUTTING

LATHE

LATHE MILLING

TRACING

SHEARING

RUBBER VULCANISATION

ADJUSTMENTS

LATHE-BORING

BORING

BARRELLING

BROACHING

TOOTHING

ELECTRICAL DISCHARGE MACHINING

FILLETING

DRILLING

MILLING

ENGRAVING

GLUEING

PART ASSEMBLY

PLANING

STRAIGHTENING

GRINDING

WELDING

DEBURRING

SLOTTING

WATER CUTTING

LASER CUTTING

LATHE

LATHE MILLING

TRACING

SHEARING

RUBBER VULCANISATION

THE MATERIALS WE PROCESS

MEASURING EQUIPMENT

SURFACE TREATMENTS AND FINISHES

ANODISING

BURNISHING

TUMBLING

CHENIFLON

CHENISIL

CHROME-PLATING

CHENIFLON

PICKLING

ELECTRO-POLISHING

PHOSPHATISING

LAPPING

POLISHING

ISOTROPIC POLISHING

MATT NICKEL-PLATING

NIPLOY

OXIDATION

SHOT BLASTING

CHEMICAL PASSIVATION

RISLAN WEAR-PROOFFACING

CARBIDE FACING

CERAMIC FACING

DIAMOND FACING

CARBIDE FACING

CHEMICAL NICKEL FACING

NICKEL-T FACING

PLASMA COATING

FACING PLASTIC FACING

SANDING

SATINISING

BRUSHING

TEFLON COATING

TENIFER

BARREL FINISHING

PAINTING

GALVANISING

BURNISHING

TUMBLING

CHENIFLON

CHENISIL

CHROME-PLATING

CHENIFLON

PICKLING

ELECTRO-POLISHING

PHOSPHATISING

LAPPING

POLISHING

ISOTROPIC POLISHING

MATT NICKEL-PLATING

NIPLOY

OXIDATION

SHOT BLASTING

CHEMICAL PASSIVATION

RISLAN WEAR-PROOFFACING

CARBIDE FACING

CERAMIC FACING

DIAMOND FACING

CARBIDE FACING

CHEMICAL NICKEL FACING

NICKEL-T FACING

PLASMA COATING

FACING PLASTIC FACING

SANDING

SATINISING

BRUSHING

TEFLON COATING

TENIFER

BARREL FINISHING

PAINTING

GALVANISING

HEAT TREATMENTS